Revisiting your own production model in the company to rethink it with a circular approach.

The Life Cycle Thinking (LCT) is a systemic structure that takes a holistic view of the production and consumption of a product or service and evaluates the impact on the environment during the entire life cycle.

LCT does not focus exclusively on a specific production cycle or on a particular product, but tries to model in an abstract way how to best define the process. The advantage of using an LCT approach is to minimize negative impacts while avoiding the transfer of these impacts from one life cycle stage to another.

When applied to product design, manufacturing processes and decision aid, LCT is a significant strategy for developing and implementing effective sustainability strategies. The Life Cycle Assessment has become an important tool for assessing the environmental impact of products and materials and companies are increasingly relying on this method for decision making .

The circular economy is a clear example of how LCT is used to change current business models which, conventionally, tend to have a linear approach by consuming excessive quantities of raw material and energy, without putting in place a clear strategy of recovery. There are several reasons why the current company is pushing to leave the linear approach to move to a more circular, such as:

- Reliable access to raw materials ( The EU strategy for raw materials );

- Reduction of costs of energy and materials;

- New technologies that allow new production techniques and innovative business models;

- Reduction of environmental impacts in the extraction of resources, energy consumption and waste production;

- Change in consumption habits by citizens;

The push of international policies towards this circular change (for example the EU strategy for the Circular Economy )

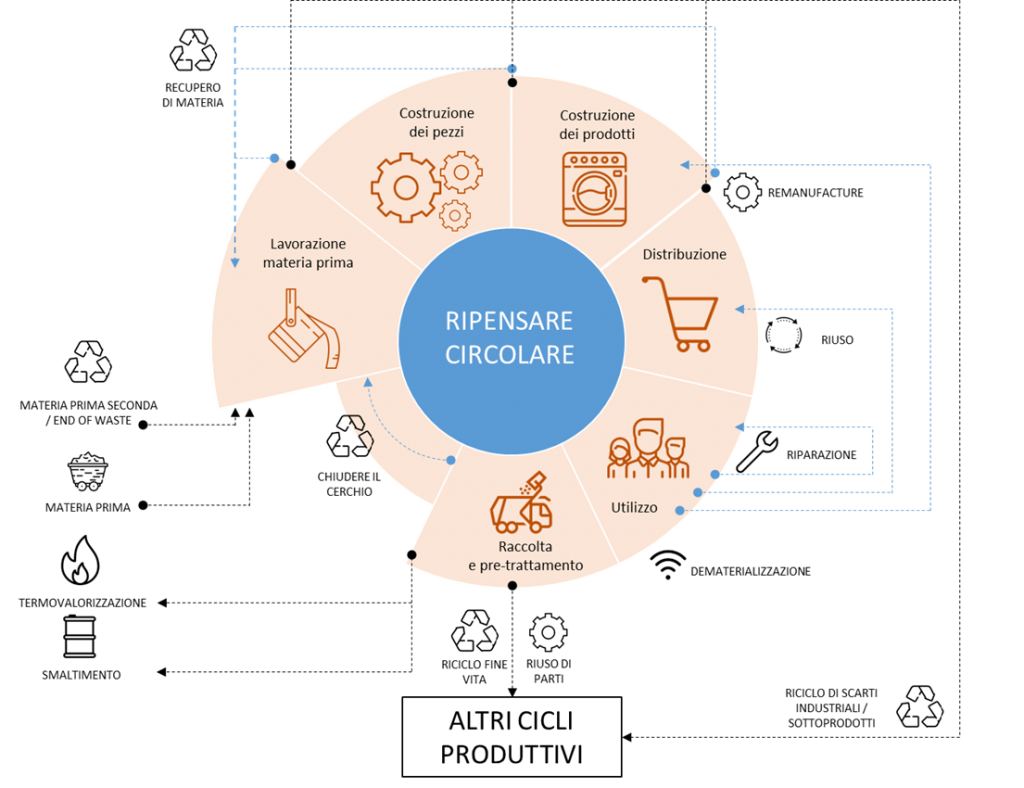

Being able to review with an eye to circularity the different phases that make up an industrial production or the creation of a service, is an effort that a company must make in order to understand where the areas in which a circular approach is most suitable can be. It is not always necessary to completely review your business model in a circular perspective, starting from the CIRCULAR BUISINESS MODEL CANVAS, you can simply observe your production cycle with an LCT approach to optimize circularity in some points. The diagram below shows how a production chain or a company, regardless of its product and / or process, can use Life Cycle Thinking to be more circular.

The first phase of a production process can involve the use of different types of materials in input: from virgin raw material, secondary raw material or End of Waste or recovered / recycled material following further production steps. Using this circular approach, it is necessary to rethink which material to use at the entrance to try to reduce the extraction of virgin materials as much as possible by favoring recycled ones. From the processing of raw material it is possible to obtain industrial waste which can however be used as input for other production cycles.

In the production phase of the various components of the product, it is essential to apply the principles of ECO-DESIGN to design and produce them. In this way, the pieces that have reached their end of life can be reused in other production cycles or, once repaired, used in new products;

For the assembly of parts for the construction of a product, reconditioned parts can be used by applying the principles of REMANUFACTURING. Production waste can be recycled and used in other production cycles

In the phase of distribution of the products, new commercial forms of sale can be envisaged to optimize their recovery once the end of life has been reached. The concept of SHARING and DISOWNERSHIP are an example of how products can be marketed by not losing ownership of those who placed them on the market, but simply by charging for their use. Once the product has reached the end of its life, it can be reconditioned, repaired or disassembled by the manufacturer himself to reuse the parts in good condition which can be useful for a new product. The whole reuse chain can also be useful for developing a new market and preventing products from being thrown as waste to be reused by other people. A company could encourage the reuse of products that are currently thrown away by the final consumer. The quality of the products of which it owns the trademark can also be certified as used products, a system that in the automotive sector has been working for some time;

The lifestyle of consumers greatly influences the way products are used. They are the ones who decide when an asset remains such because it is still usable or when it becomes waste, who decide what the market “trends” are and the opportunity to reintroduce into the supply chain the same products or parts of them. Repair, Reuse and Remanufacturing are important tools that a company can disseminate and encourage by making consumers aware of the importance of circularity of the supply chain. The dematerialization of some services and products themselves can encourage the circular economy of the system;

After use, a product can become waste and follow specific rules for its recovery and treatment. This phase is essential to make a selection of materials and create homogeneous supply chains of waste which can then be more easily sent for treatment to be reinserted into a new production cycle. There are also mechanisms such as EXTENDED MANUFACTURER LIABILITY that allow you to incentivize the collection and recycling of waste to be used again in the same supply chain or in another production sector.

Download Unit 3.6 (to download the pdf you must subscribe to the website/newsletter by releasing your email)

Learn more about the other Didactic Units

INTELLECTUAL AND INDUSTRIAL PROPERTY RIGHTS – LIMITATION OF USE

© Copyright Reserved – This Educational Unit and the related editorial content conveyed are the subject of intellectual and industrial property of Circularity Srl – Benefit Society and as such protected.